Understanding the sustainability and circularity of the shoe industry

Authored by – Shamika Kulkarni, Stathia Bampinioti, Ankit Vora, Caroline Huskey

Sustainability has become a hot issue in the footwear industry, and it will continue to be a major issue in the upcoming years.

Worldwide footwear consumption has doubled every 20 years, from 2.5 billion pairs in 1950 to more than 20 billion pairs of shoes in 2005. As a result, the worldwide consumption of footwear per capita has also considerably increased, from 1 pair of shoes per year for every person in the world in 1950 to almost 2.6 pairs of shoes in 2005. In the European Union, footwear consumption has increased by 22% from 2002-2005 to reach 2.3 billion pairs of shoes.

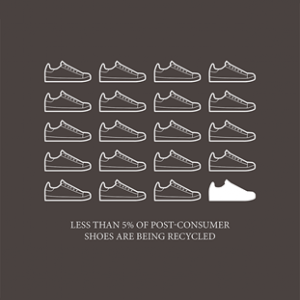

No significant progress has been achieved in the development of recycling solutions for mixed footwear products. The most up-to-date figures from 2007 state that in the EU, “the waste arising from post-consumer shoes will reach 1.2 million tonnes per year”. In fact, less than 5% of post-consumer shoe waste is being recycled, while the majority is sent in landfills.

One of the main reasons is that shoes are designed to fulfill a varied range of consumer requirements regarding functionality, design, and styles, and thus, they contain a complex mix of materials. It is estimated that approximately 40 different materials are used in the manufacturing of a shoe, making the complete separation and reclamation of material streams in an economically sustainable manner really difficult.

Many big and small companies specialized in footwear have taken action towards a more sustainable future, trying to optimize the full footprint of a product from the supply chain through the end of its life. They have worked on material innovations, along with recycling and upcycling initiatives for post-consumer waste, and they have aligned their growth paths with their new goals and values. However, taking a more cautious look in the footwear industry, we still believe that even the most sustainable big players have not very concrete plans on how to achieve sustainability and reduce waste across the value chain yet. What is more, usually, the sustainable products offered tend to be not affordable for the mass population.

The motivation of our team is to analyze the available solutions to propose a more comprehensive and scalable business model for affordable and sustainable footwear. We specifically want to tackle the following United Nations Sustainable Development Goals and their underlying targets:

- UN SGD 12.5 By 2030, substantially reduce waste generation through prevention, reduction, recycling, and reuse by 2030.

- UN SGD 12.4 By 2020, achieve the environmentally sound management of chemicals and all wastes throughout their life cycle, in accordance with agreed international frameworks, and significantly reduce their release to air, water and soil in order to minimize their adverse impacts on human health and the environment

Among the several start-ups or companies working on these sustainable goals, we found WAO, which started on a crowdfunding platform and, after reaching their goal, they were able to open their e-commerce activities in 2018. WAO seems to have created a great ecosystem of suppliers that can support a circular economy in footwear.

Project Value Proposition

Given the high level of material waste as a result of the apparel industry, our solution focuses specifically on shoes and will reduce the waste of making shoes by using natural, reusable materials. WAO was created as the first entirely ecological shoes made with natural, innovative and sustainable materials. This is the environmentally-conscious effect resounding from the cyclical nature of WAO: all the 12 parts of the shoes come from the earth and return to it at the end of their cycle.

Setting Goals & Measuring Progress

- Increase the percentage of new shoes made that are 100% recyclable versus traditional wasteful methods

- Reduce material footprint per capita for WAO consumers by 50% in line with UN SDG #12 goal to “By 2030, achieve the sustainable management and efficient use of natural resources.”

- Increase national recycling rate & tons of material recycled in line with the goal to “By 2030, substantially reduce waste generation through prevention, reduction, recycling and reuse.”

WAO’s Business Model

WAO’s business model is to create an online direct-to-consumer brand to sell entirely ecological shoes to customers worldwide with manufacturing operations in Italy. The company’s mission is to “develop footwear in a way that the environmental impact is reduced to a minimum, both in terms of material and construction”[1].

WAO has developed a transparent supply chain and identified natural, innovative and sustainable materials to make each of the 12 components of the shoe and these materials can be returned back to the environment at the end of the shoe’s life cycle. All of the company’s suppliers are based in Italy and the company has released the information of each supplier on its website as a mark of its commitment to transparency. Below is a list of materials used for each shoe component:

- the upper is made of wood fibre and hemp

- the insole is composed of cork and coconut fibre

- liner and laces in hemp and organic cotton

- the dyes come from natural pigments

- the sole is biodegradable and can be thrown into the compost heap

The company has released two separate designs so far – the low top (available in 6 different colours) and the high top (available in 1 colour), both of which are made with the same set of materials mentioned above. Each pair of shoes retail for €180 plus additional shipping depending on the customer’s location. WAO does not plan to release seasonal products but rather have a permanent collection of footwear.

WAO is targeting the environmentally conscious consumer that is willing to pay a premium for more sustainable footwear. With its designs, WAO is also looking to take advantage of the recent trend towards casual sneakers that are not meant for heavy physical activity.

WAO plans to stick to e-commerce to reach its consumers, mainly through social media marketing and keyword searches on search engines. It has an active Instagram presence where it engages with its almost 5K followers.

The company also offers customers the option to return their shoes to the company so that the components can be sustainably returned back into the environment, creating a circular business model with minimum environmental impact. Furthermore, the company plans to form associations with non-profits that work towards environmental protection and animal welfare, and has committed to donating 4% of its revenue to such organizations. In this way, the company has aligned its sustainability and financial goals – the more shoes it sells, the higher the impact towards reducing the use of unsustainable raw materials in footwear production.

As the company grows its operations, it could face challenges in expanding its supply chain to procure large volumes of materials such as hemp that may not be easily available due to low worldwide demand. Additionally, the company’s price point of €180 per pair is significantly higher than the average shoes in the market, reducing its target customer base. The company might find it challenging to reduce its production costs while maintaining its commitment to using 100% sustainable materials. Finally, customers are not currently accustomed to returning their shoes after use and changing this consumer behaviour will be difficult.

Challenging WAO’s business model

The intentions of WAO’s business model are definitely noble and aligned with UN SDG 12. However, we believe the impact being made is currently limited and our analysis yields the following findings:

Customer Acquisition – While finding and targeting customers with a high willingness to pay may not be a problem for WAO on account of their social media campaigns, they nevertheless have a limited presence (5k followers is a drop in the ocean), and need to up the ante when it comes to reaching their niche target market especially given the low scroll-through and click-through rates on social media platforms. Finding appropriate social media influencers would help WAO to widen their reach to the youth creating a pull effect for their products. To sustain the purchasing behaviour among this customer segment, alignment of objectives would be essential to highlight the sustainability advantage of purchasing their shoes creating brand recall and brand associations linked to sustainable shoes and circular economy.

Procurement Process – Based on the current demand estimates and forecasts, the local procurement approach helps WAO to further reduce its carbon footprint. However, when the scaling takes place resulting in higher demand and correspondingly higher procurement, approaching raw material suppliers located further away would increase WAO’s category 2 emissions. This should be taken into account while offsetting their carbon emissions or managing donations.

Modularity – We believe this business model is most suitable for modularity concept we learnt in POM, especially given their limited and long term nature of collections / models. This could be used better by WAO to truly scale up their manufacturing effort and hopefully gain some economies of scale along the process as well. They have already tried to limit the number of components in their shoes, and improving modularity would take them one step further towards process improvements for efficient and sustainable operations.

Collections and Recycling – A critical source of raw materials could be through the recycling of the shoes returned by current users. However, shockingly, this is only an option to the existing consumer. WAO should invest in building a more robust return model such as refund / rebate of pre-specified amount when the shoe is shipped / transported back to WAO’s manufacturing facilities for recycling. This could further add on to their category 3 emissions, and hence could also be mitigated by associations with local authorities and non-government organisations to handle the recycling of the shoe. With this solution, WAO will however effectively lose out on an incremental source of raw materials. Preparing a detailed emission breakdown analysis akin to a cost benefit analysis could help WAO decide which approach to follow to be environmentally more sustainable. A refund / rebate option could help with decreasing the price-point of the shoe which could currently be an inhibiting factor for some of their target consumers.

We believe the above point is one that could be tested relatively easily in various markets and if proved successful could be scaled to other companies not just WAO itself.

- Test case – Recycling and collection of shoe waste by local municipal authorities / governments. Tie-up with local authorities to arrange a used shoe collection drive to build critical mass of various kinds of shoes. Find a stakeholder involved in recycling, who can help to break down the shoes into individual components, and sort into recyclable / not. Provide the statistical base of this experiment to the local authority as well as published in the location it has been collected from to showcase the impact on the environment.

- Proposed next steps – Carbon emissions could be tracked especially for local collection and recycling of those shoes earmarked as sustainable such as WAO’s shoes. This metric could then be provided to the shoe manufacturers as a benchmark that they would need to improve upon in order to become more efficient from a recycling perspective thus making the process of collection / transportation to original shoe manufacturers more sustainable than local recycling or disposal.

Stakeholder Analysis

In order to assess the scalability of WAO’s business model, we started with a stakeholder analysis. We believe the customers, raw material suppliers, local government authorities, non government organisations, industry coalitions, and WAO’s own shareholders and employees are the critical stakeholders WAO should take along with in their decision making for best results. Currently, we believe WAO considers only the customer and non-government organisations in their effort. Aligning with local government authorities could give them some economic benefits such as tax breaks, lower cost utilities etc. It could also allow WAO to have a larger impact on regulations for the shoe and apparel industry going forward both by influencing the regulation and being preferentially aware through some lobbying efforts. Aligning objectives with non-government organisations will help not just to improve the overall sustainability agenda, but also to gain a stronger foothold in their customer base through endorsements and word of mouth publicity. Alongside targeting the right customer segments, we believe WAO can definitely benefit from finding the right social media influencer with shared sustainability goals and a larger follower base that could be used to increase WAO’s brand presence and recall.

Barriers to Scale

The major barriers to scaling WAO’s and other sustainable shoe business models are:

- Price point – this is still quite unattractive for the mass customer base in order to truly make a widespread impact in the show industry and expand beyond the current niche audience.

- Limited recycling efficiency – Technology for recycling needs to be improved over time in order for the recycled materials to become a truly viable and competitive source of raw material procurement. Currently the sustainable shoe industry is limited by sourcing of more environmentally conscious material or limited efficacy (and lifespan) of recycled material such as Nike’s recycled plastic shoe.

- Logistics – Shipping, transportation and physical (brick & mortar) sales will impact the carbon emissions and footprints of such companies resulting in smaller scaling from a visibility standpoint for the end customers thus not allowing companies like WAO to build up their demand forecasting improving economies of scale for their shoes.

- Industry Coalitions – Whole shoe sustainability is a favourite topic for discussions at the industry forums, there needs to be much more of a spotlight especially on the business models and technologies of those companies that are making a difference.

In Conclusion

The solution to improving sustainability in the footwear industry extends beyond individual business models such as WAO and will need an industry-wide effort, influencing customer behaviour and increasing component of sustainable shoe sales among overall footwear sales. We believe WAO’s sustainable procurement of materials creating a sustainable and recyclable shoe is an excellent starting point. Efforts undertaken by large companies like Nike and Adidas are also commendable, however, scaling up this industry is of crucial importance if we want a sizable contribution in the future to reach the stated ambition of reaching UN SDGs.

[1] https://www.italianshoes.com/en/wao-the-shoes-with-the-eco-effect/